- POST-MORTEM ANALYSIS OF REFRACTORY MATERIALS

- REFRACTORY TESTING

- SCANNING ELECTRON MICROSCOPE

- GLASS DEFECT ANALYSIS

The refractory materials in a glass furnace have to resist not only extremely high temperatures, but also the corrosion coming from the glass melt and the furnace atmosphere. The post-mortem analysis of corroded refractory material after furnace service provides essential information about, and insights into, the correlation between furnace performance and furnace operation on the one hand, and refractory wear on the other. The interpretation of the microscopic observations makes it possible to explain the different corrosion mechanisms and, thus, provides valuable details and clues for a possible optimisation of future furnace performance and operation.

In order to simulate accelerated industrial working conditions and to predict the degradation of refractories, elaborate testing procedures are performed.

Corrosion

resistance

The

resistance

to thermal

and chemical

stresses is

tested with

the dynamic

finger test

and the

static plate

corrosion

test

according to

the

International

Commission

on Glass,

Technical

Committee 11

(the

so-called

TC11).

In the

dynamic

finger test,

a

cylindrical

sample is

rotated in a

platinum

crucible

together

with molten

glass. The

test is

carried out

with

predefined

parameters

(temperature,

time) and

the

reduction in

diameter at

fluxline

(three phase

contact) is

measured.

The

corrosion

rate can

also be

determined

by measuring

the decrease

in length

(forced

convection

at the

rotating

cylinder

face) as a

function of

time and at

various

rotation

rates.

In the

static plate

corrosion

test, sample

platelets

are immersed

into the

glass melt.

After the

chosen time

the fluxline

depth of the

corroded

samples is

measured.

This test is

carried out

with four

samples

under the

same test

conditions

and is,

therefore,

an

appropriate

method to

compare and

evaluate

certain

refractory

grades

together. An

international

round-robin

investigation

within the

Technical

Committee 11

of the

International

Commission

on Glass

confirmed

the good

reproducibility

of the

static plate

corrosion

test, and

the TC11

recommended

it as the

standard

corrosion

test.

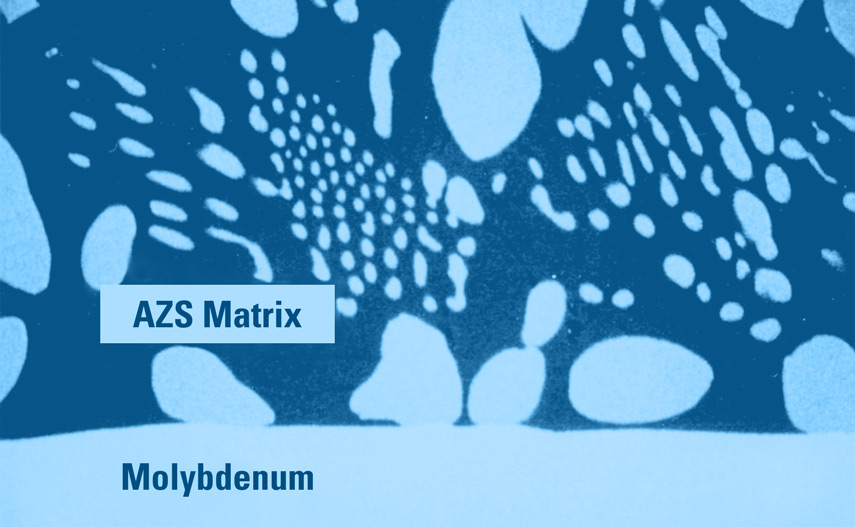

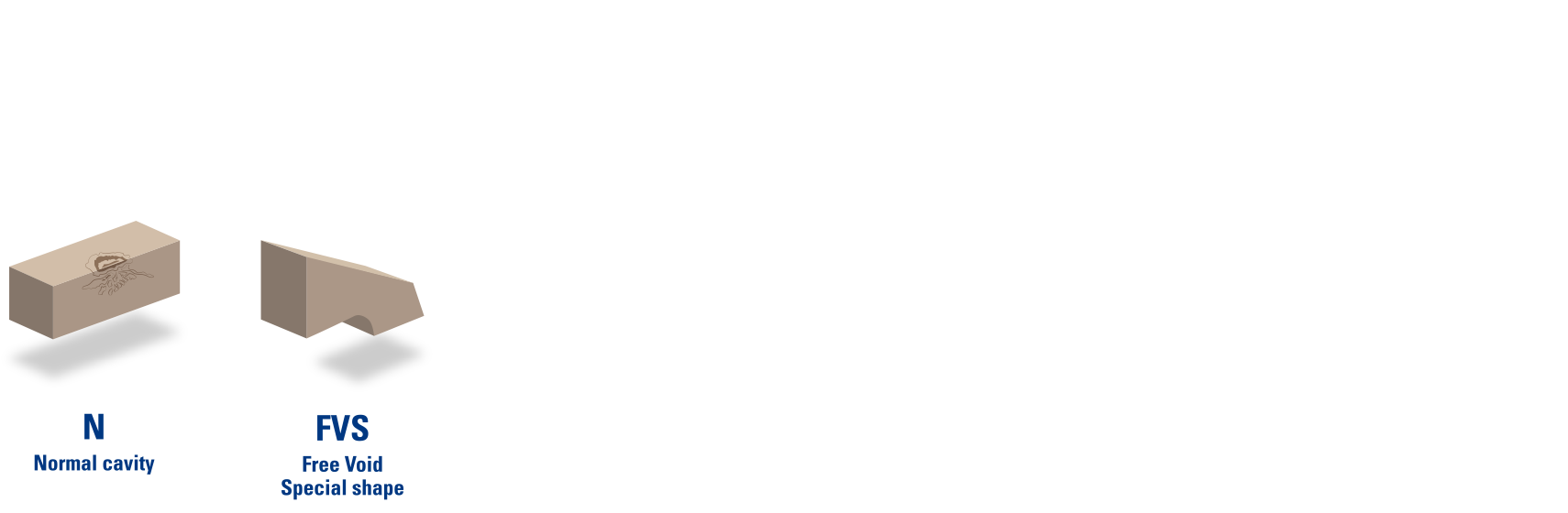

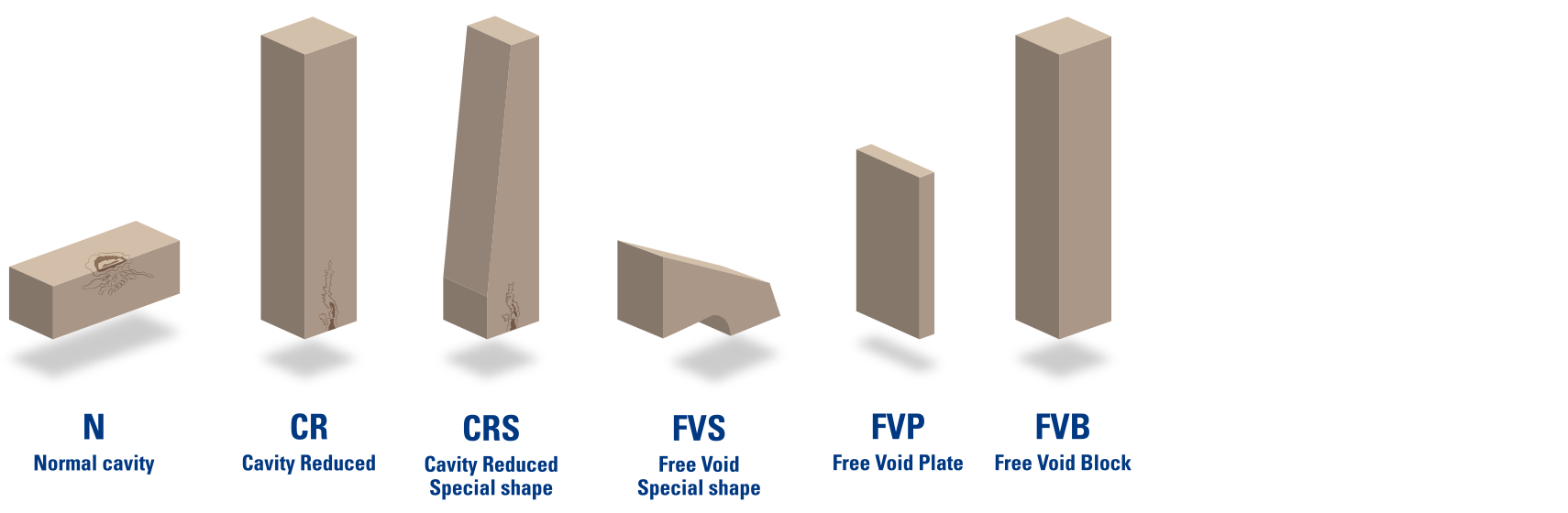

Stone

formation

Due to the

interaction

of the glass

melt with

fused cast

AZS, solid

stones can

be

generated.

The defect

potential is

evaluated by

counting

this kind of

inclusion

inside the

remaining

glass after

each

corrosion

test.

Blistering

The tendency

of fused

cast AZS to

form bubbles

in contact

with molten

glass is

evaluated

with an

especially

developed

test

procedure in

which

standard

glass is

molten in a

fused cast

AZS

crucible.

The number

of bubbles

contained in

the glass

samples

after test

melting is

an

indication

of

blistering

potential.

The tendency

to release

bubbles is

expressed in

bubbles/gram

glass,

following

the

terminology

of glass

defects of

the

International

Commission

on Glass.

Exudation

In order to

evaluate the

expulsion of

glassy

phase, a

simulation

of the

load-free

preheating

stage, which

the

refractory

blocks in a

melting

furnace

undergo, is

performed by

heating the

test

material up

to

temperatures

comparable

to real

furnace

operation

conditions.

The test

procedure

follows the

recommendations

of the

Technical

Committee 11

of the

International

Commission

on Glass.

The

experimental

data of

REFEL

refractories

show that

for

temperatures

higher than

1500°C there

is only

limited

exudation

which

decreases

slowly with

service

time.

Vapour

attack

This test

method

according to

ASTM is

performed to

evaluate the

resistance

of

refractories

in glass

melting

furnace

superstructures

to vapour

attack. The

vapour test

method may

also be

useful for

evaluating

refractories

in other

applications

where vapour

attack

occurs.

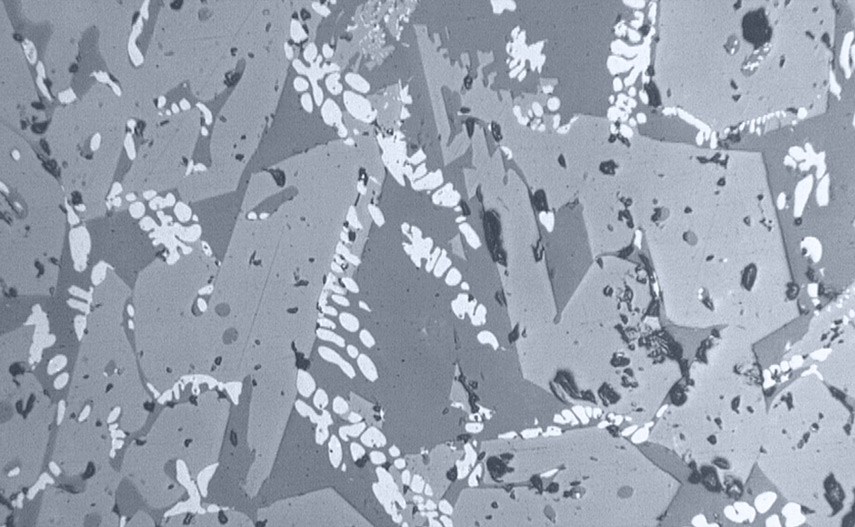

The Scanning Electron Microscope (SEM) is used for the high resolution analysis of very fine crystalline structures as well as the analysis of glass chemistry and glass defects such as impurities and inclusions. Fragments of the material to be examined or ground sections – gold-vaporised surfaces for structure, carbon-vaporised surfaces for chemical composition – are scanned by an electron beam and displayed on a monitor for analysis. Due to the high degree of magnification, the special arrangement of the structure components and pores in the material under investigation become visible. It is, therefore, possible to qualitatively determine the existing elements during the investigation of impurities, and to make semi-quantitative statements on the chemical composition of the structure components of ground areas.

Glass defects

can arise

for various

reasons,

such as

unmolten raw

materials or

the

extensive

use of

recycled

glass

cullet, and

result in

the

occurrence

of unsightly

and partly

dangerous

inclusions.

Furthermore,

also melting

conditions

and their

influence on

the

refractory

materials in

the furnace

can

stimulate

glass

defects.

Through the

identification

of glass

defects

REFEL’s

experts can

give

comments and

recommendations

based on

their

long-term

experience

regarding

possible

causes as

well as

possible

preventive

or

corrective

measures to

avoid glass

defects in

the

future.

In doubtful

cases, the

results of

optical and

electron

microscopes

are verified

by X-ray

diffraction

analysis in

REFEL’s

state-of-the-art

laboratory.